Virtual Event replay

Supply Chain of Reuse

Check out this virtual event, all about the supply chain of reuse:

Write your awesome label here.

Event Summary:

VivoBarefoot: Tandi Tuakli

Head of Revivo

With a mission to keep their products out of landfills, VivoBarefoot leverages innovation to extend the life of their products, provide value for money to customers, and ultimately ‘Keep Vivos on feet.’

The company has integrated 4 key approaches to achieve this including a customer repair service, partnership with children clothing rental company Bundlee, a take back program, and finally refurbish for resale program. Facilitating these programs is a circular network model built on relationships with retail, rental, and repairs partners.

Additionally, added promotions such as the 100 day warranty with full-refund and 10% discount on future purchases for every pair of used Vivos returned incentivize customers to bring back products, all fueling towards the hope that customers can become our greatest suppliers when retrieving worn products.

In expanding reuse efforts at the company, the focus will be on scaling up the take back program, more R&D in refurbishing and recycling products, and extending services to more geographies to develop a regional approach.

In expanding reuse efforts at the company, the focus will be on scaling up the take back program, more R&D in refurbishing and recycling products, and extending services to more geographies to develop a regional approach.

GE HealthCare: Siva Balakrishnan

General Manager of Lifecycle Solutions

From the $10 trillion healthcare industry, around $8.5 trillion is spent on OECD countries which accounts for approx 1 billion people. As emerging markets grow upwards of 8 billion people, the healthcare needs in these regions (non-OECD countries) will also increase, meaning that the industry will need to expand their focus and the evolution of care will become more critical.

In enabling healthcare accessibility and driving care across the world, the most important factor is affordability. This can be achieved through circularity by adding a generation to the market through reuse, refurb and remanufacture. GE HealthCare retrieves 7,000 pieces of equipment annually that then undergoes a refurbish and remanufacturing process and is sold to tier 4 and 5 suppliers in America and across the world. These products are similar to new equipment, backed by the same warranty and recertified to the original specification, only with one generation of technology removed.

In enabling healthcare accessibility and driving care across the world, the most important factor is affordability. This can be achieved through circularity by adding a generation to the market through reuse, refurb and remanufacture. GE HealthCare retrieves 7,000 pieces of equipment annually that then undergoes a refurbish and remanufacturing process and is sold to tier 4 and 5 suppliers in America and across the world. These products are similar to new equipment, backed by the same warranty and recertified to the original specification, only with one generation of technology removed.

All in all, circularity provides an affordable healthcare solution.

Additionally the company’s recycling program harvests parts, recycles or reuses 17 million pounds of material, of which 94-96% is diverted from landfills, and continues to explore better avenues to recycle the 4-6% that does reach the landfill. GE HealthCare leverages reuse efforts to extend the life of machines to then affordably expand its use across the world with the purpose of creating a world where healthcare has no limits.

Additionally the company’s recycling program harvests parts, recycles or reuses 17 million pounds of material, of which 94-96% is diverted from landfills, and continues to explore better avenues to recycle the 4-6% that does reach the landfill. GE HealthCare leverages reuse efforts to extend the life of machines to then affordably expand its use across the world with the purpose of creating a world where healthcare has no limits.

B2X: Simon Dunn

Vice President of Business Development

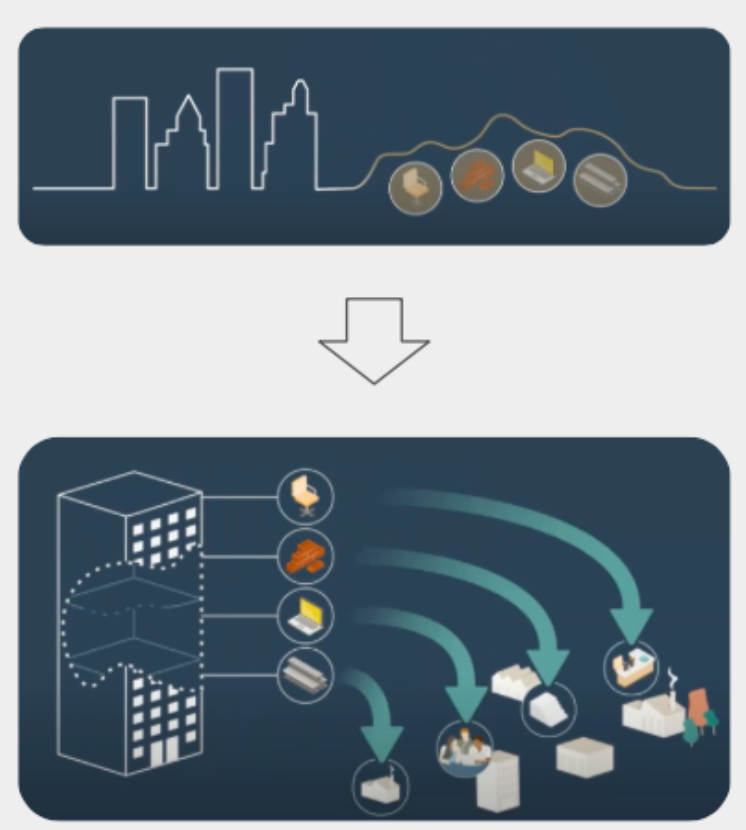

B2X employs a holistic circular service model to provide on-site deployment of technology, preventative maintenance and support, manage returns, recycling, handle repairs and upgrades, and true end of life solutions.

The company provides a robust supply chain with their expansive 4PL network of service and logistics necessary to facilitate the growing demand for circular services, and difficult to scale for individual businesses to develop for their product. B2X has brought uberization to the service market with the strive to gather the best parts available in the market across the spectrum of industries to create better outcomes, and a platform for players of any size to participate.

The enablers of this model have been their IT and systems platform that helps deploy solutions effectively. B2X will continue to develop partnerships and harness collaboration to grow in various regions whilst also harnessing the power of technology.

Rheaply: Sushma Kittali-Weidner,

Vice President of Product

Rheaply strives to deliver circularity for every business to not only reduce waste and divert it from landfills, but also to build communities to facilitate such reuse efforts.

The company presented the use case of reusing furniture, fixtures, and equipment (FFE) at any organization. Rheaply challenges sourcing new FFE, usually bought in large volumes, such as chairs and tables, for remodeling or new commission projects. Instead, by building a secondary life marketplace, Rheaply promotes the reuse of idle assets, avoiding millions of dollars in expenditures, achieving carbon avoidance by reducing scope 3 emissions, and diverting waste from landfills to meet zero waste goals. This model works across industries, examples include diverting 14,000 pounds from landfill for hospitals, recapturing $264,000 value in the biopharma industry and $271,000 value in higher education.

However, to enable and scale this further, Rheaply emphasizes the need for a mindset shift in organizations and buyers. Reuse cannot be an afterthought, but instead a deliberate plan. This can be operationalized by increasing visibility on assets, sourcing locally from second life marketplaces, and partnering with manufacturers to include take back and repair programs. Whereas, buyers need to become better stewards of the resources they purchase and consider how they use the products. A mindset shift from all parties can further drive reuse efforts to better solve internal and community challenges.